The work process of our team company is guided by the principle of the most complete satisfaction of consumer demand in the field of pneumatic equipment.

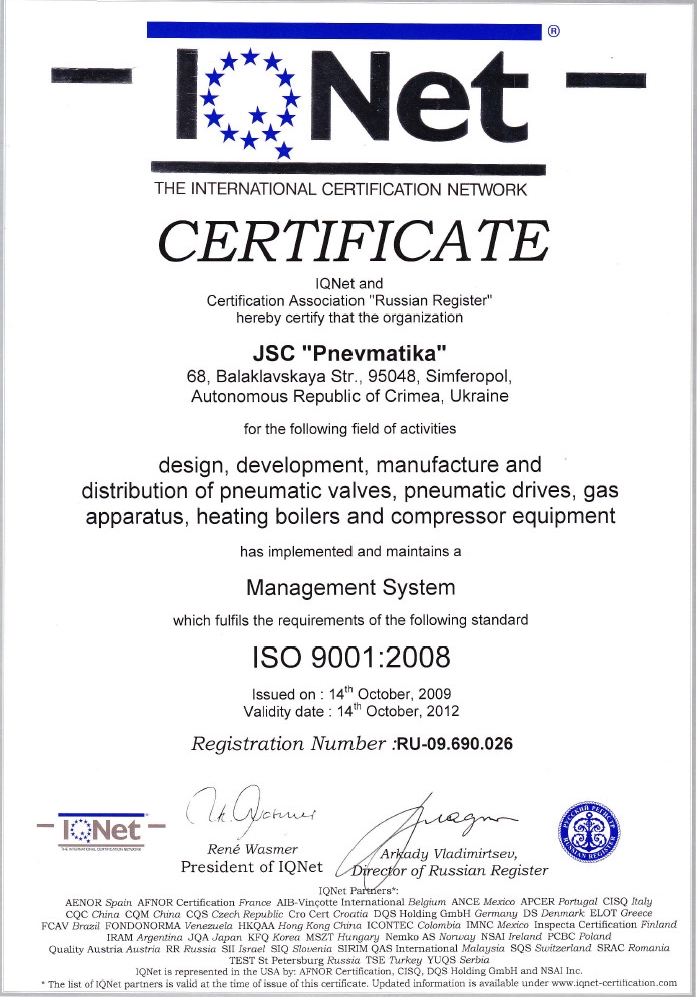

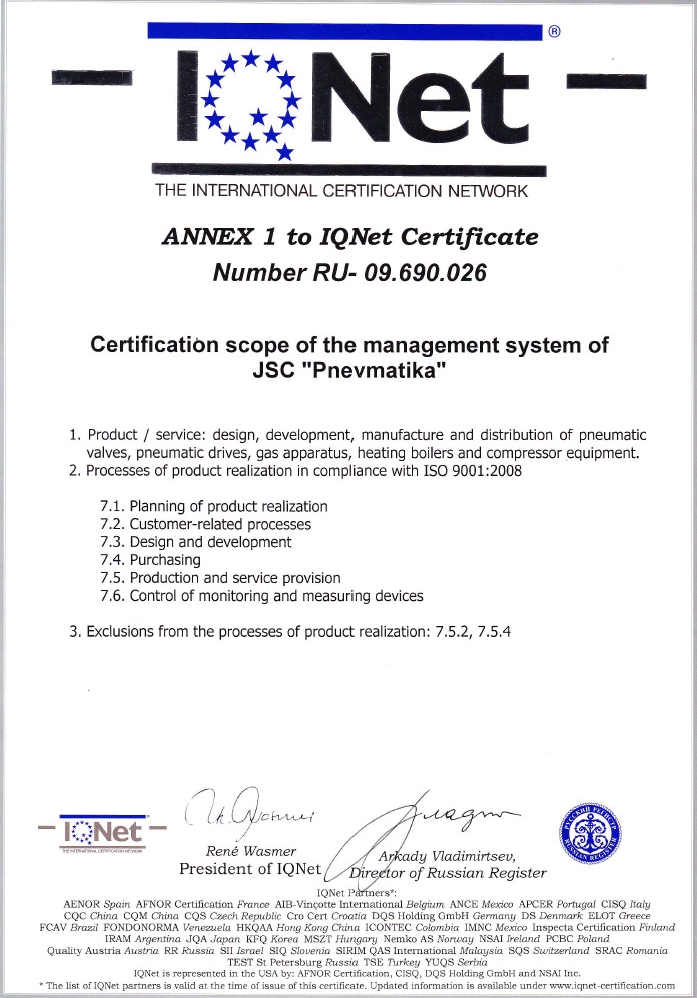

We produce products that meet the requirements of international standards and are able to satisfy the most demanding tastes.

The advantages of Pneumatics are clearly shown in the mechanization and automation of the most mass and typical operations such as: clamping, fixing, turning, installation, transportation, packaging, etc. At the same time, human participation in heavy and monotonous work is excluded or minimized, and labor productivity is significantly increased

OJSC Pneumatics is a reliable long-term partner of the leading enterprises of the industrial complex of Ukraine: "Donetsk metallurgical industrial complex", "Novokramatorsky machine-building Complex", "Mariupol Complex the name of Ilicha", "Azovstal", "Dnipro metallurgical Complex", and a reliable partner in the modernization of technological equipment of modern enterprises. A wide range of offers for pneumatic equipment provides air preparation from the compressor to the drive mechanism. All products of OJSC "Pneumatics" are manufactured on high-tech equipment: "TRUMATIC 2000" - coordinate-carving machine (Germany);" TRUMABEND 80S " - coordinate-bending machine; CNC processing center, the use of the most modern materials is provided-"we don't save money on quality".

We produce products that meet the requirements of international standards and are able to satisfy the most demanding tastes.

The advantages of Pneumatics are clearly shown in the mechanization and automation of the most mass and typical operations such as: clamping, fixing, turning, installation, transportation, packaging, etc. At the same time, human participation in heavy and monotonous work is excluded or minimized, and labor productivity is significantly increased

OJSC Pneumatics is a reliable long-term partner of the leading enterprises of the industrial complex of Ukraine: "Donetsk metallurgical industrial complex", "Novokramatorsky machine-building Complex", "Mariupol Complex the name of Ilicha", "Azovstal", "Dnipro metallurgical Complex", and a reliable partner in the modernization of technological equipment of modern enterprises. A wide range of offers for pneumatic equipment provides air preparation from the compressor to the drive mechanism. All products of OJSC "Pneumatics" are manufactured on high-tech equipment: "TRUMATIC 2000" - coordinate-carving machine (Germany);" TRUMABEND 80S " - coordinate-bending machine; CNC processing center, the use of the most modern materials is provided-"we don't save money on quality".

ABOUT THE COMPANY

LADIES AND GENTLEMEN!

The skill level of engineering capability supports at the proper level design features of our products, simply eye-catching ergonomic design and is not inferior to the technical characteristics of leading enterprises of foreign production. Our specialists are always ready for an open dialogue to satisfy the most "capricious" consumers of our equipment.

On our website you can find the entire list of manufactured equipment:

On our website you can find the entire list of manufactured equipment:

Customers of our equipment in the CIS countries can use our dealer network - this will help save the cost with customs services.

Pneumatic equipment for all industries

PNEUMATICS

Copyright (C) 2008 OJSC Pneumatics. All right reserved.

•

Pneumatic Equipment (compressed air preparation Devices. Drive mechanism. Air distributor. Mini and control regulative

equipment. Drive);

•

Boiler equipment (Gas valves, filters. Domestic and industrial gas boilers);

•

Compressor equipment;

•

Machines for processing PVC profiles.

General Director - Nikolay Vasiliev

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Technical Director - Viktor Ivanovich Kislyi

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Chief accountant - Lyudmila Levanova

Phone +73652441218

E-mail: gb@pneumoao.ru

Commercial Director – Astaf'ev Sergei Vladimirovich

Tel / Fax +73652520550; mobile +79788577755

E-mail: astafyev@pneumoao.ru

Skype: astafyevserg

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Technical Director - Viktor Ivanovich Kislyi

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Chief accountant - Lyudmila Levanova

Phone +73652441218

E-mail: gb@pneumoao.ru

Commercial Director – Astaf'ev Sergei Vladimirovich

Tel / Fax +73652520550; mobile +79788577755

E-mail: astafyev@pneumoao.ru

Skype: astafyevserg

CONTACTS

Quality Director-Oleg Tsvetkov

Phone +73652443719

E-mail: pneumo@pneumoao.ru

Head of the supply Bureau-Alexander V. Kichy

Phone +73652443719; Fax +73652443895 mobile +7978857666

E-mail: omts1978@mail.ru

ICQ: 199317406

Chief designer - Sergey Nikolaevich Zhidov

Phone +73652441635

E-mail: pneumo@pneumo.net.ua

Phone +73652443719

E-mail: pneumo@pneumoao.ru

Head of the supply Bureau-Alexander V. Kichy

Phone +73652443719; Fax +73652443895 mobile +7978857666

E-mail: omts1978@mail.ru

ICQ: 199317406

Chief designer - Sergey Nikolaevich Zhidov

Phone +73652441635

E-mail: pneumo@pneumo.net.ua

General Director - Nikolay Vasiliev

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Technical Director - Viktor Ivanovich Kislyi

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Technical Director - Viktor Ivanovich Kislyi

Reception +73652441155

E-mail: pneumo@pneumoao.ru

Marketing and sales Department:

Chief accountant - Lyudmila Levanova

Phone +73652441218

E-mail: gb@pneumoao.ru

Commercial Director – Astaf'ev Sergei Vladimirovich

Tel / Fax +73652520550; mobile +79788577755

E-mail: astafyev@pneumoao.ru

Skype: astafyevserg

Phone +73652441218

E-mail: gb@pneumoao.ru

Commercial Director – Astaf'ev Sergei Vladimirovich

Tel / Fax +73652520550; mobile +79788577755

E-mail: astafyev@pneumoao.ru

Skype: astafyevserg

OJSC "Pneumatics" is using such types of technologies: carving of details, injection molding and chill mould of aluminum alloys, pressing of plastic and rubber products, mechanical processing of parts on machine equipment, including automatic machines and CNC machines, winding of electric coils, painting of parts with polymer coating and enamels, electroplating, laser welding, gas welding, electric welding of various types, technology of carving parts from sheet material on high-performance CNC stamping complexes of the German company "TRUMPF”, technology of high-speed counter boring and milling of equipment in tool production on a modern coordinate counter boring machine, technology of powder metallurgy of non-ferrous and ferrous metals, tool production, gear production and others.

COMPLEMENTARY SERVICES

The purpose of a piston compressor is to supply compressed air to pneumatic machines and mechanisms. Oil-injected piston compressors are widely used in many industries, and oil-free compressors are used in food and medical applications.

Main advantages:

-low cost

-ease of maintenance

-ease of management

-maintainability

-resistance to frequent switching on and off of the device

-the ability to operate in harsh conditions (at high humidity, in a wide temperature range, with strong air pollution)

- compressors manufactured by OJSC Pnevmatika are a reliable, high-quality and inexpensive source of compressed air. The heart of our compressor is the compressor block of the Italian company FIAC.

Main advantages:

-low cost

-ease of maintenance

-ease of management

-maintainability

-resistance to frequent switching on and off of the device

-the ability to operate in harsh conditions (at high humidity, in a wide temperature range, with strong air pollution)

- compressors manufactured by OJSC Pnevmatika are a reliable, high-quality and inexpensive source of compressed air. The heart of our compressor is the compressor block of the Italian company FIAC.

Piston compressor

Since October 2008, the enterprise has been operating a multipurpose complex of machine tools from the world's leading manufacturers. The advantage of these machines is that the use of a driven tool, drilling operations, milling with various interpolations, turning operations with heavy cutting conditions and high-precision machining are concentrated in one machine.

MULTI-PURPOSE MACHINE SET

DAHLIH MCV-720 Vertical Machining Center:

Semi-automatic pipe bending machine SOCO SB-38NC

Wire EDM Machine Aristech CW-30 / 25A

Semi-automatic pipe bending machine SOCO SB-38NC

Wire EDM Machine Aristech CW-30 / 25A

FANUC GOODWAY CNC Turning Center:

Goodway GA-2000M

Goodway GA-2600

Goodway GS-200MS

Goodway GA-2000M

Goodway GA-2600

Goodway GS-200MS

High quality tool manufacturing (dies, molds for rubber, plastics and molds for aluminum alloys) on modern imported CNC equipment at affordable prices.

PRODUCTION OF RIGGING

Product

•

Catalogue

•

Compressors

•

Filter element

•

Hydraulic equipment

•

Home appliance mounts

•

Road blockers (Bollards)

Compressors

Screw compressors

Designed to supply compressed air to pneumatic tools, devices, mechanisms and various industrial facilities.

Screw compressors are highly reliable and durable due to the absence of valves and parts that make reciprocating movements, as well as the use of highly reliable asynchronous motors.

KBB 0,6/10

Screw compressors

Designed to supply compressed air to pneumatic tools, devices, mechanisms and various industrial facilities.

Screw compressors are highly reliable and durable due to the absence of valves and parts that make reciprocating movements, as well as the use of highly reliable asynchronous motors.

KBB 0,6/10

| Classification | |

| Options | Data |

| Productivity, m³ / min, at 1MPa | 0,6 |

| Compressed air pressure at the compressor outlet, max, MPa | 1 |

| Electric motor power, kW | 7.5 |

| Protection degree of electrical equipment | IP20C |

| Receiver volume, l. | 270 / - |

| The amount of oil, l. | 6 |

| Oil content in compressed air, at the compressor outlet, mg / m³ | 3 |

| Overall dimensions, mm | 1650/1300 width 700/560 height 1200/820 Weight, kg 260/110 |

Additionally, the compressor can be equipped with the following devices

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

KBB 1,9/10

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

KBB 1,9/10

| Classification | |

| Options | Data |

| Productivity, m³ / min, at 1MPa | 1,3 |

| Compressed air pressure at the compressor outlet, max, MPa | 1 |

| Electric motor power, kW | 15 |

| Protection degree of electrical equipment | IP20C |

| Receiver volume, l. | 500 / - |

| The amount of oil, l. | 9 |

| Oil content in compressed air, at the compressor outlet, mg / m³ | 3 |

| Overall dimensions, mm | 1730/1100 width 890/890 height 1340/870 Weight, kg 400/270 |

Additionally, the compressor can be equipped with the following devices

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

KBB 4/10

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

KBB 4/10

| Classification | |

| Options | Data |

| Productivity, m³ / min, at 1MPa | 1,3 |

| Compressed air pressure at the compressor outlet, max, MPa | 1 |

| Electric motor power, kW | 15 |

| Protection degree of electrical equipment | IP20C |

| Receiver volume, l. | 500 / - |

| The amount of oil, l. | 9 |

| Oil content in compressed air, at the compressor outlet, mg / m³ | 3 |

| Overall dimensions, mm | 1730/1100 width 890/890 height 1340/870 Weight, kg 400/270 |

Additionally, the compressor can be equipped with the following devices

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

KBB 7/10

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

KBB 7/10

| Classification | |

| Options | Data |

| Productivity, m³ / min, at 1MPa | 6 |

| Compressed air pressure at the compressor outlet, max, MPa | 1 |

| Electric motor power, kW | 45 |

| Protection degree of electrical equipment | IP20C |

| Receiver volume, l. | - |

| The amount of oil, l. | 25 |

| Oil content in compressed air, at the compressor outlet, mg / m³ | 3 |

| Overall dimensions, mm | 1550 width 960 height 1800 Weight, kg 1000 |

Additionally, the compressor can be equipped with the following devices

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

Filter element (cartridge) polypropylene

Filter element (cartridge) polypropylene, designed for cleaning drinking water from water supply systems. In addition, it is possible to filter other liquids-wine, alcohol, oils, acids and alkalis.

Four-line hydraulic valves with electromagnetic control 4GR3

Four-line spool hydraulic valves are designed for hydraulic drives of machine tools, presses and other stationary machines.

Wall bracket for mounting microwave ovens TNP 191

Wall bracket for mounting microwave ovens and other household appliances.

Brackets for LCD TVs and plasma panels

Road blockers (Bollards)

Bollards belong to the category of anti-RAM equipment and are the most reliable road blockers.

Automatic bollards also can be classified as anti-terrorist barriers.

Air preparation unit - filter regulator with pressure gauge and semi-automatic condensate drain

Air handling unit + automatic condensate drain

Air dehumidifier up to class 0 (dew point reduction by 15 °)

Compressed air dryer with 40 ° dew point reduction (Additional drying of the filter element cartridge is required)

Drying device with regeneration of the silikogel cartridge of the filter element (dew point reduction by 40 °)

Compressors with a frequency converter that changes the angular speed of rotation of the screw block in proportion to the actual consumption of the consumer network at a given pressure at the compressor outlet, allows you to save up to 6% of electricity with an increase in the value of the outlet pressure for every 0.1 MPa

Screw compressors are highly reliable and durable due to the absence of valves and reciprocating parts, as well as the use of highly reliable induction motors. The uniform supply of compressed air eliminates the need for air collectors, the complete balance of the rotors eliminates the need for special foundations, therefore the compressor is installed on a site that takes loads only from its own weight. Compressor stations consist of a screw compressor, an electric drive, an oil separator and an automation system. The system of smooth adjustment of productivity and the presence of perfect automation allows to achieve significant energy savings and minimize the operator's labor. All compressors are thoroughly tested before being sent to the customer.

Filter element (cartridge) polypropylene

Filter element (cartridge) polypropylene, designed for cleaning drinking water from water supply systems. In addition, it is possible to filter other liquids-wine, alcohol, oils, acids and alkalis.

Four-line hydraulic valves with electromagnetic control 4GR3

Four-line spool hydraulic valves are designed for hydraulic drives of machine tools, presses and other stationary machines.

Wall bracket for mounting microwave ovens TNP 191

Wall bracket for mounting microwave ovens and other household appliances.

Brackets for LCD TVs and plasma panels

Road blockers (Bollards)

Bollards belong to the category of anti-RAM equipment and are the most reliable road blockers.

Automatic bollards also can be classified as anti-terrorist barriers.